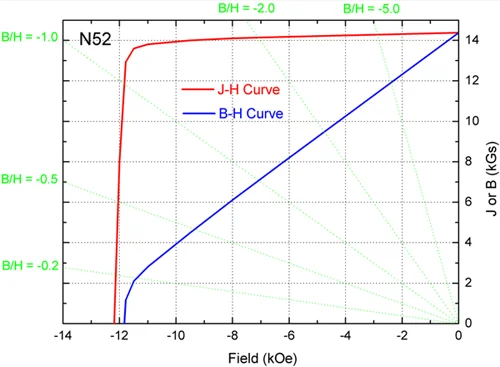

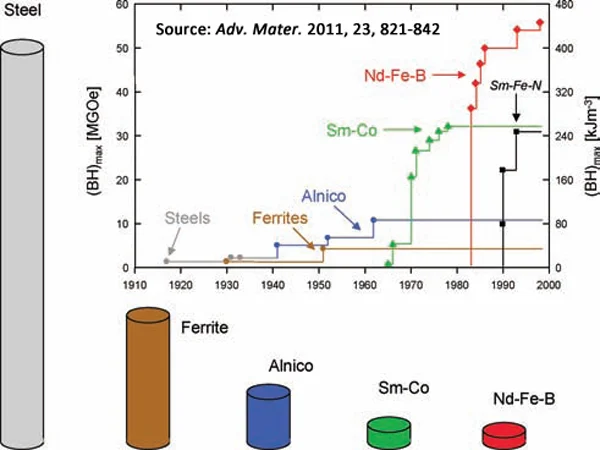

N52 magnets are the most powerful magnets on the market, although there are other stronger magnets developed in the lab. Having the top level of maximum energy product 50-53 MGOe or 398-422 kJ/m^3, they are regularly used in high performance and/or miniature applications such as electronic products, micro sensors and automobiles. Most of N52 magnets have round, block and ring shapes, other irregular magnets including trapezoid, triangle, step and conical shapes can also be produced as per custom requirements. N52… Read More

Continue Reading