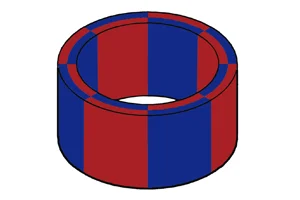

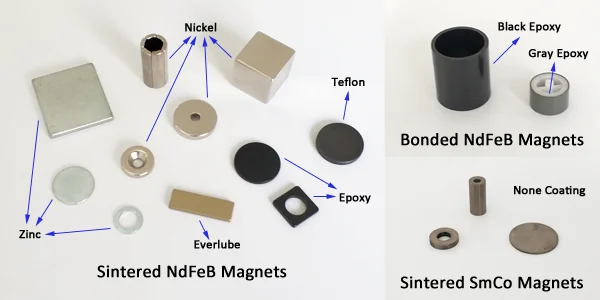

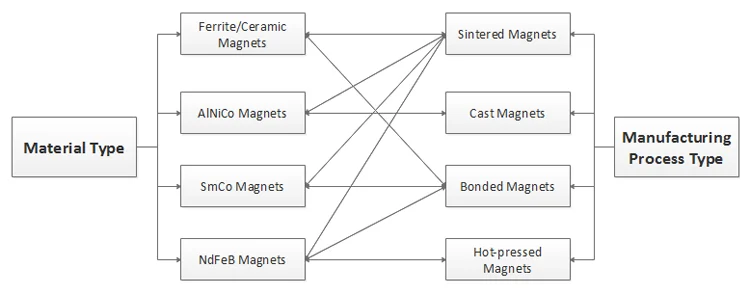

Radially oriented neodymium iron boron (NdFeB) ring magnets are state-of-the-art ring magnets with diverse magnetization patterns in radial direction. In general, they provide high performance and cost-effective alternatives to arc/segment magnets. According to different production processes, radially oriented NdFeB ring magnets include sintered NdFeB ring magnets, bonded NdFeB ring magnets and hot-pressed NdFeB ring magnets. single pole radially ring magnet multi-pole radially ring magnet (straight) multi-pole radially ring magnet (skew)

Continue Reading