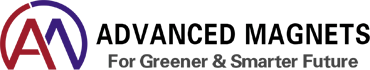

N52 magnets

N52 magnets are the most powerful magnets on the market, although there are other stronger magnets developed in the lab. Having the top level of maximum energy product 50-53 MGOe or 398-422 kJ/m^3, they are regularly used in high performance and/or miniature applications such as electronic products, micro sensors and automobiles. Most of N52 magnets have round, block and ring shapes, other irregular magnets including trapezoid, triangle, step and conical shapes can also be produced as per custom requirements. N52… Read More

Continue Reading

PTFE coated Magnet Rods for Test of Magnetic Impurities in Li-ion Battery Materials

PTFE coated magnet rods consist of neodymium magnets, steel washers and PTFE shell. They are also called Teflon coated neodymium magnet rods. With PTFE shell, they are resistant to corrosion by strong acid and alkali solutions. Their surface magnetic field strength reaches 6000-7000 gausses, or higher as per requirements. In this article, PTFE coated magnet rods applied for test of magnetic impurities in Li-ion battery materials is described. A Test Method of Magnetic Impurities in Li-ion Battery Materials Magnetic impurities… Read More

Continue Reading

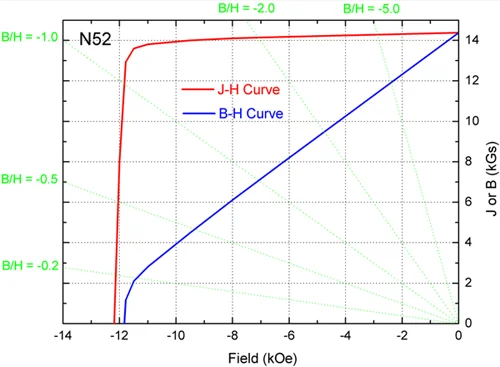

N35 Magnets

N35 magnets are strong neodymium magnets with excellent cost performance. They are widely used neodymium magnets for 3C products, magnetic holding, magnetic separation. Most of N35 magnets are round, block and ring shaped, some of them have countersunk holes for mounting. Besides, other irregular shaped magnets can be customized as per personalized requirements as well. N35 magnets maximum working temperature is 80 degrees Celsius or 176 degrees Fahrenheit. However, their long term operating temperature is recommended not to exceed 60-70… Read More

Continue Reading

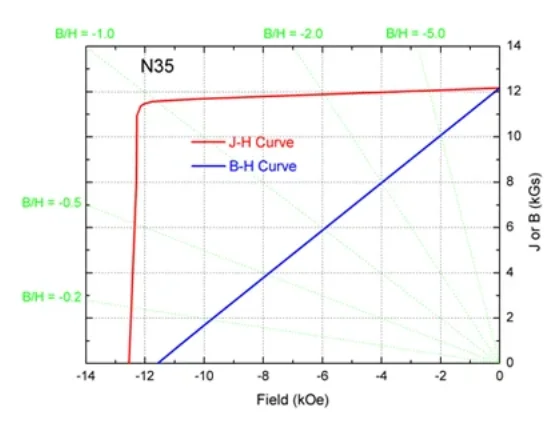

Neodymium Magnet Raw Material PrNd Metal Price Trend 2022

Rare earth PrNd metal price trend is the vane of neodymium magnet price trend Neodymium magnets contain rare earth elements, iron, boron and other elements. The rare earth elements in the magnets account for 28-35% by weight. As rare earth raw material prices are much higher than those of other raw materials, their cost accounts for 80-98% of the total raw material cost. Especially affected by the rising market of rare earth raw materials since 2021, as of the time… Read More

Continue ReadingRare earth-iron-boron (REFeB) Magnets IEC Standard

The International Electrotechnical Commission (IEC) published the standard IEC 60404-8-1:2015 for magnetically hard materials (permanent magnets). In this standard, the part of Rare earth-iron-boron (REFeB) magnets’ magnetic properties and densities is shown in the table below. In the REFeB magnets, the RE element is mainly neodymium (Nd), and the manufacturing method is a powder sintering process, so REFeB magnets are also known as sintered NdFeB magnets. China supplies most of the sintered NdFeB magnets in the global market, for those… Read More

Continue Reading

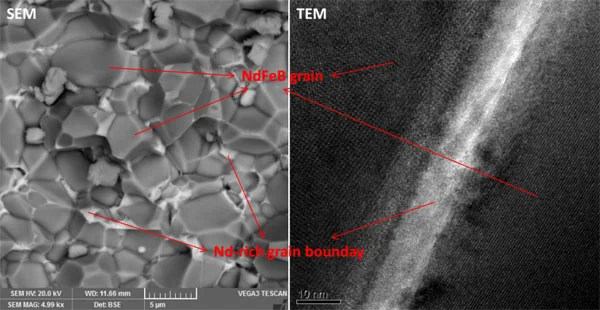

Sintered NdFeB Magnet Composition and Microstructure

Sintered NdFeB Magnet Composition Sintered NdFeB magnet contains three essential elements: rare earth neodymium, iron and boron. Nd atoms, coupling with ferromagnetic Fe atoms, help the magnet obtain high remanence Br and maximum energy product (BH)max, which makes it extraordinary compared with other permanent magnets. Although B element has only around 1 wt% in the magnet, it is necessary for the intermetallic phase stability, so the magnet has stable magnetic properties. In commercial sintered NdFeB magnet, Nd element is usually… Read More

Continue Reading

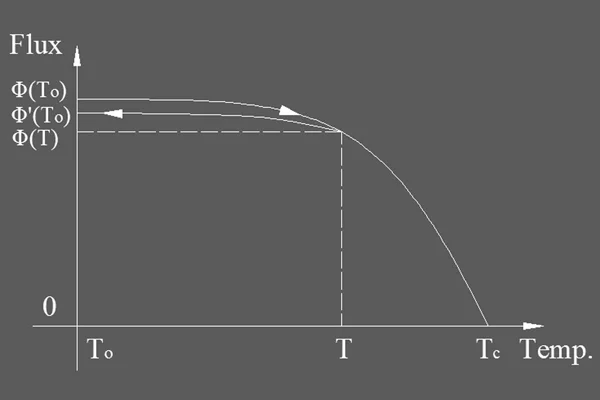

Permanent Magnet Maximum Working Temperature

Permanent magnets are widely applied in various motors, sensors/instruments and electronics, their temperatures almost vary more or less during work. These temperature variations are resulted from eddy current effect and/or ambient temperature variation. Due to thermal fluctuation and magnetic domain evolution, a permanent magnet loses some or all magnetic flux when its temperature elevates. Here comes a question, how high temperature can a permanent magnet withstand to work? For a commercial permanent magnet, the upper temperature limit is called maximum… Read More

Continue Reading

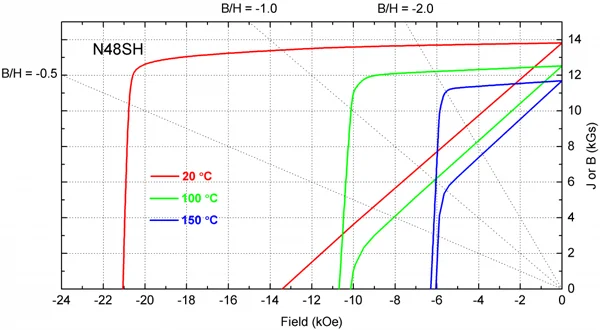

What are Permanent Magnets Temperature Coefficients α and β?

A permanent magnet’s magnetic properties change as a variation of temperature. For a permanent magnet, remanence (Br) and intrinsic coercivity (Hcj or Hci) are two major parameters, it is important to consider their changes with corresponding temperature variation at work. In order to describe the relative changes, they are calculated according to the following two formulas: α = [Br(T1)-Br(T2)]/Br(T1)/[ T1-T2]×100 (1) β = [Hcj(T1)-Hcj(T2)]/Hcj(T1)/[T1-T2]×100 … Read More

Continue Reading

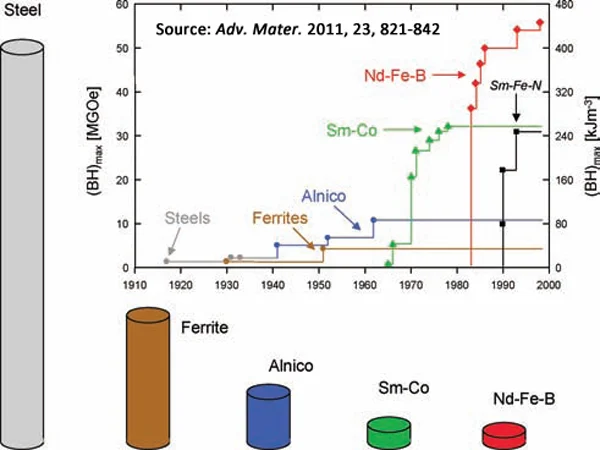

Strongest Commercial Permanent Magnet

Researchers and engineers have never stopped their steps to discover and develop novel permanent magnets since 1910s, and several types of permanent magnets had been commercialized and they have been widely used in motion, energy, electronics, medical and other high technologies in our daily life. However, little breakthrough has been taken in the past 18 years of the 21st century. In the current market, almost all types of commercial permanent magnets (ferrite, NdFeB, SmCo and AlNiCo, etc.) were discovered and… Read More

Continue Reading

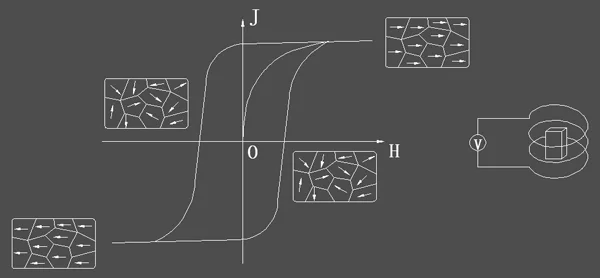

Magnetize a Magnet and Demagnetize a Magnet

The basic way to magnetize a magnet is using a coil, i.e. an electromagnet, to generate a magnetic field. The generated magnetic field increases as the charging current increases, it drives micro magnetic domains of a magnet rotate to the magnetization direction. When all the micro magnetic domains aligned along the same direction, the magnet is magnetized to the saturation state. Demagnetizing a magnet is the opposite process of magnetizing a magnet as described above. Just alternative the charging current… Read More

Continue Reading

Do Magnets ever Lose Their Magnetism or Get Weaker?

Actually permanent magnets are not permanent. A Permanent Magnet is a material which has ability to resist demagnetization, including filed demagnetization and thermal demagnetization. The ability is characterized by a physical parameter called coercivity. In regard to field demagnetization, if a demagnetizing field or reverse field is smaller than a permanent magnet’s coercivity, the permanent magnet will keep the same magnetic flux (the demagnetizing process is linear and reversible when the demagnetizing field is lower than a threshold value) or… Read More

Continue Reading

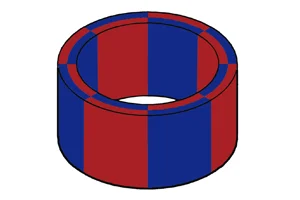

Radially Oriented NdFeB Ring Magnets

Radially oriented neodymium iron boron (NdFeB) ring magnets are state-of-the-art ring magnets with diverse magnetization patterns in radial direction. In general, they provide high performance and cost-effective alternatives to arc/segment magnets. According to different production processes, radially oriented NdFeB ring magnets include sintered NdFeB ring magnets, bonded NdFeB ring magnets and hot-pressed NdFeB ring magnets. single pole radially ring magnet multi-pole radially ring magnet (straight) multi-pole radially ring magnet (skew)

Continue Reading

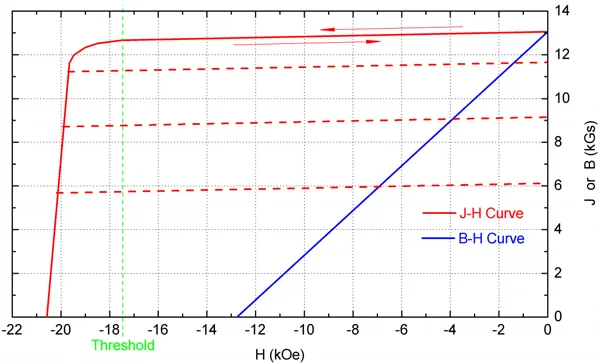

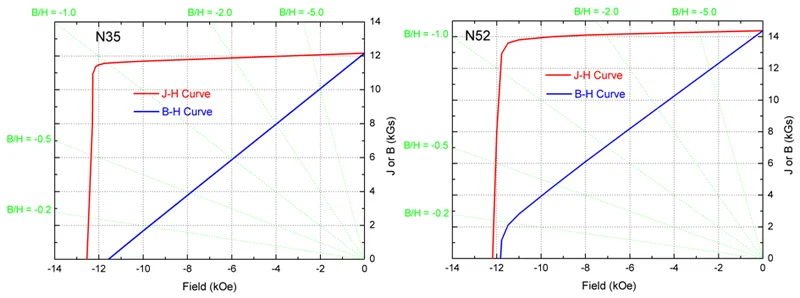

What is the Difference between N35 and N52 Magnets?

What are N35 and N52 magnets? Seen from their grade strings, both of them are sintered neodymium iron boron (NdFeB) magnets. These two magnets have the same intrinsic coercivity Hcj level higher than 12 kOe (in CGS unit) or 955 kA/m (in SI unit). It is also obviously seen that their maximum energy product (BH)max are around 35 and 52 MGOe, respectively. This huge difference means that the N52 magnets have around 49% more energy than that of the N35… Read More

Continue Reading

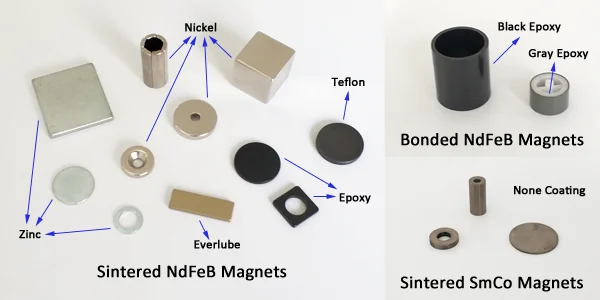

Corrosion Resistance of Rare Earth Permanent Magnets

In the Rare Earth Permanent Magnets family, the 1st generation 1:5 type SmCo magnets and 2nd generation 2:17 type SmCo magnets have high corrosion resistance due to the high cobalt content. Just like ferrite/ceramic magnets and AlNiCo magnets, SmCo magnets usually do not need any treatment for applications. The 3rd generation NdFeB magnets, however, are not the same. Although they have superior magnetic properties, they are more vulnerable to corrosion in humid environments, resulting in the deterioration of magnetic properties… Read More

Continue Reading

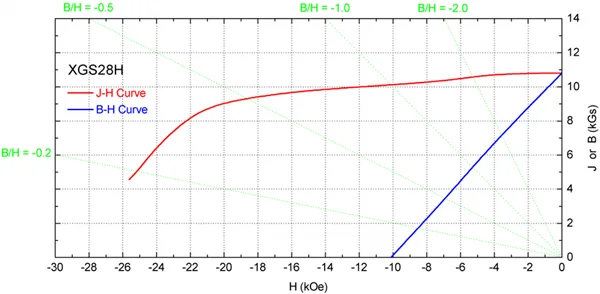

Sintered SmCo Magnet Grades

Samarium cobalt (SmCo) magnets include 1:5 type (SmCo5) and 2:17 type (Sm2Co17) magnets. Both types of SmCo magnet grades basically include three parts, i.e. “letter 1” + “number” + “letter 2”. The three parts in sintered SmCo magnet grades present material type, (BH)max value (in CGS unit) and Hcj level, respectively. The part “letter 1” are “XG” and “XGS” for sintered SmCo5 and Sm2Co17 magnets, respectively. Besides, the Hcj levels of sintered SmCo5 magnets include “default” (Hcj ≥ 15 kOe)… Read More

Continue Reading