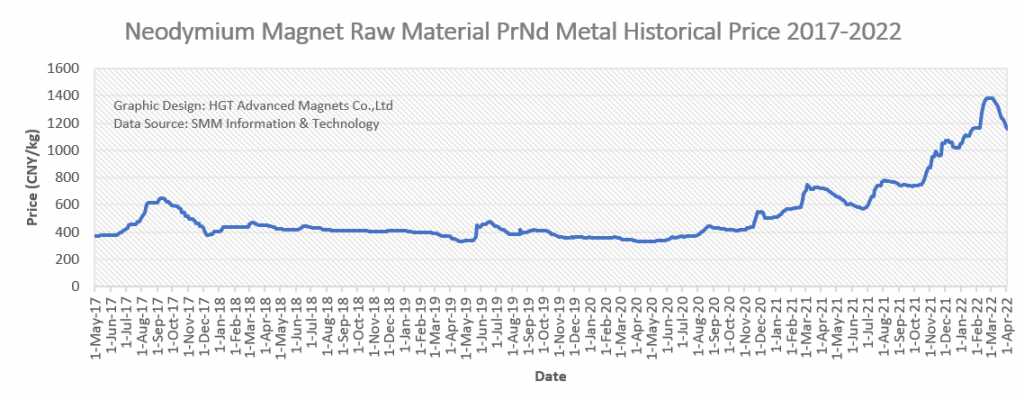

Rare earth PrNd metal price trend is the vane of neodymium magnet price trend Neodymium magnets contain rare earth elements, iron, boron and other elements. The rare earth elements in the magnets account for 28-35% by weight. As rare earth raw material prices are much higher than those of other raw materials, their cost accounts for 80-98% of the total raw material cost. Especially affected by the rising market of rare earth raw materials since 2021, as of the time… Read More

Continue Reading