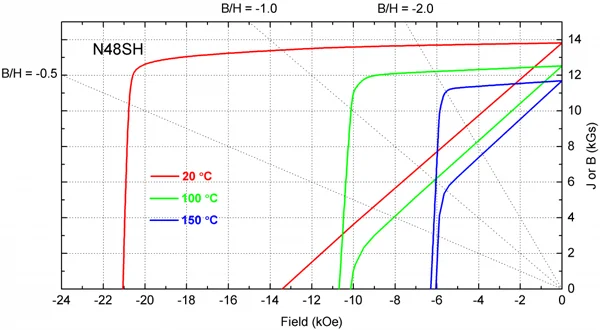

A permanent magnet’s magnetic properties change as a variation of temperature. For a permanent magnet, remanence (Br) and intrinsic coercivity (Hcj or Hci) are two major parameters, it is important to consider their changes with corresponding temperature variation at work. In order to describe the relative changes, they are calculated according to the following two formulas: α = [Br(T1)-Br(T2)]/Br(T1)/[ T1-T2]×100 (1) β = [Hcj(T1)-Hcj(T2)]/Hcj(T1)/[T1-T2]×100 … Read More

Continue Reading